SAP Business One enables medium-sized companies to manage their production processes end-to-end - from initial requirements to the accounting mapping of finished products. The close integration of master data, planning, execution and control therefore ensures that production costs remain transparent and stock movements are traceable at all times.

1. production master data: The basis of the production process

1.1 Article master data and procurement method

An article can only be produced if it is correctly maintained in the article master. Two properties are crucial here:

- Warehouse-managedThe article must enable inventory management.

- Procurement method: ManufactureOnly then does the material requirements planning take this article into account as a product to be manufactured.

This makes the article available for production orders and the requirements calculation.

1.2 Parts list (Bill of Materials, BOM)

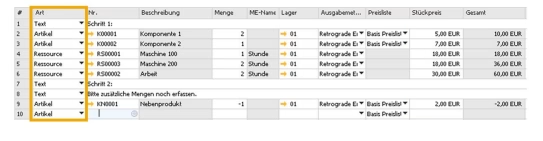

The bill of materials defines all components of a product. In SAP Business One, a distinction is made between different types - for production, however, the Production bill of materials for use. This contains:

- The finished product (superordinate component)

- All required materials and resources (subordinate components)

In this way, it forms the calculatory and technical basis for Production orders and the scheduling run.

1.3 Resources and capacity planning

Resources such as machine time or employee deployment are separately definable master data. They contain

- Capacity data

- Cost rates

- Calendar availability

The resources and their costs are automatically included in the evaluation of the finished product and support bottleneck analyses.

1.4 Routing and route sections

Optionally, production parts lists in Route sections can be organised. This allows finer control of the production stages. Each routing consists of sequenced stages that:

- Define work sequence and duration

- Used for lead time and capacity planning

- The following form a basis for the feedback of work steps

2. creation of the production order

2.1 Manual creation

A production order (PA) can be created directly via the menu:

Production > Production order

This method is useful for customised products or for short-term requirements.

2.2 Order-related production (pull principle)

When a customer order is received for an item to be produced, this can automatically trigger a PA. Via the Procurement assistants checks the system:

- Whether the item is available

- Whether production is necessary

If the stock is missing, a suitable PA is suggested.

2.3 Material requirements planning (MRP)

The MRP module analyses requirements (customer orders, forecasts, assembly requirements) and stocks along the time axis. If net requirements are determined, the MRP assistant creates suggestions for production orders - taking SAP Business One into account:

- Delivery times

- Throughput times

- Storage ranges

Example: If a subassembly is required whose production time is 5 days, the system automatically suggests the earliest possible start time.

3. processing of the production order

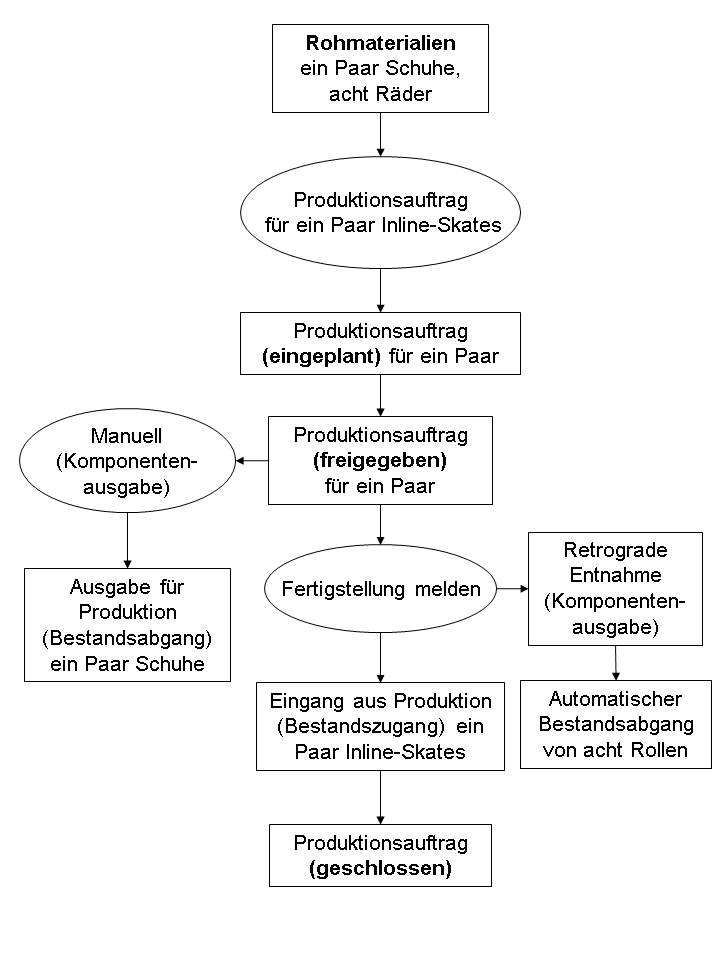

3.1 Status change: From Scheduled to Released

A newly created production order starts in the status Scheduled. Only by manually switching to Released editing is possible:

- Stock withdrawals are capitalised

- Working hours and feedback can be recorded

3.2 Component provision: manual vs. backflush

Materials are supplied to the production process in two ways:

- BackflushComponents are automatically consumed on completion.

- Manual outputAdvance withdrawal via the document Output for production - This is particularly necessary for serialised or batch-managed items.

3.3 Accounting-relevant stock movements

The withdrawal of components is relevant for accounting purposes. Postings with capitalised perpetual inventory management:

- Credit note on the Stock account of the component

- Load on the Work in progress account (WIP)

This entry reflects the ongoing capital commitment in the production process.

3.4 Notification of completion and stock receipt

Once production has been completed, the Input from production:

- The finished product is posted to the warehouse stock

- Valuation is carried out in accordance with the selected valuation method (e.g. moving average)

- WIP account is balanced

You can dispose of unused materials via Return components return to the warehouse

3.5 Completion of the production order

The final step is the status change to Closed. In the process:

- The order is matched against the warehouse and accounting

- A closing entry is generated

- The order is removed from the list of open documents

4. management, control and transparency

4.1 Linking diagram: The graphical overview

SAP Business One offers the Linkage plan a visual representation of all document relationships:

- From customer order to receipt from production

- All stock movements included

This enables complete traceability of every production run.

4.2 Series and batch management

Both raw materials and finished products can be labelled with serial or batch numbers. This offers:

- Traceability via transaction reports

- Quality control

- Obligation to provide evidence for recalls

Example: The serial number report shows which order has generated which serial number.

4.3 Cost, time and status monitoring

The tab Overview in the production order provides information about

- Planned vs. actual costs

- Time deviations

- Resource utilisation

In addition, the Open production orders report, to maintain an overview of running processes.