Material requirements planning (MRP) in SAP Business One provides the purchasing and production process with data to optimise stock levels via the relevant processes. The aim is therefore to have the right quantity and quality of the required goods in the right place at the right time in a cost-optimised manner.

Data basis of the MRP in SAP Business One

Material requirements planning (MRP) calculates requirements by first calculating the Stock for the higher-level items, followed by the stock levels, the corresponding lower-level items are analysed.

These data are used in the process:

- Number of items in stock

- Receipts from orders

- Production orders

- Stock transfers to the higher-level warehouse

- Incoming advance invoices

- recurring transactions on the input side

The system then subtracts the demand from

- Number of items in stock

- Receipts from orders

- Production orders

- Stock transfers to the higher-level warehouse

- Incoming advance invoices

- Recurring transactions on the input side

General preparations for material requirements planning

There are some general requirements as a basis for correct material requirements planning in SAP Busines One. Most of the preparatory work concerns the material master data. If you are not operating with fixed order points, but seasonal fluctuations or other values play a role, forecasts are used.

Preparation of the article master data

The article master data should be maintained in the system with as many details as possible. This includes the general determination of the planning method, procurement method, order intervals, order multiples, minimum order quantity, lead times and tolerance days as well as the maintenance of the purchase price and required purchase quantities.

The forecasts in MRP with SAP Business One

A forecast is a way of predicting the future demand for your finished products. Since not all customer orders are received according to a fixed schedule that would allow for a constant production or purchasing plan, the purchasing department often has to operate with forecasts. Forecasts are based on historical sales data, current sales data and data on future sales.

In SAP Business One, you can generate a forecast manually or automatically. When one

the automatic method, SAP Business One creates a forecast on the basis of the

historical sales from sales orders or deliveries and outgoing invoices. You can add several forecasts if required. You can then select a forecast in an MRP run.

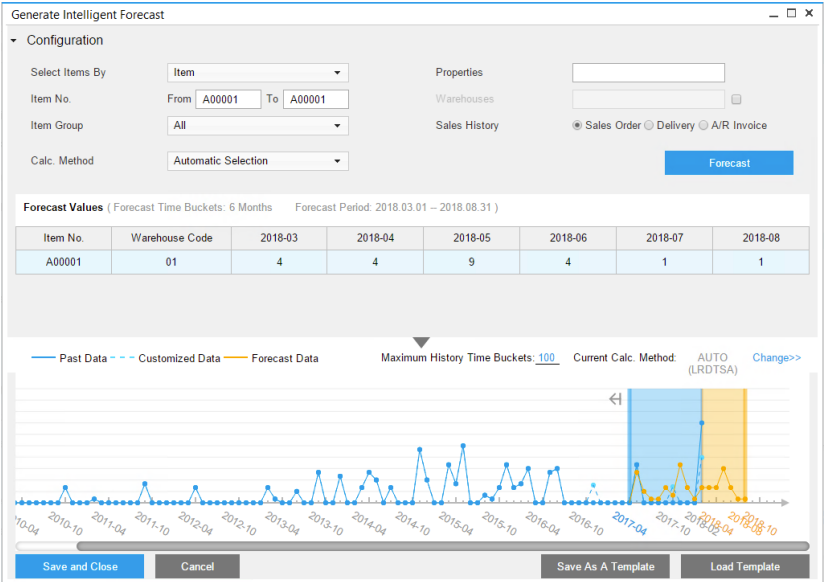

Intelligent forecasting in SAP HANA

In SAP Business One / HANA, there is an additional option for generating forecasts as part of material requirements planning. The so-called "intelligent forecasts" are available for this purpose. Ready-made statistical models are provided for this purpose:

- TESM (Triple Exponential Smoothing)

- LRDTSA (Linear Regression with Damped Trend and Seasonal Adjust)

The proposals generated in this way are visualised and can be further processed as such.

The Disposition Wizard in SAP Business One

Disposition Assistant in SAP Business OneThe MRP assistant is the central element in material requirements planning with SAP Business One. It summarises the various requirements triggers and parameters to create an MRP proposal. You can set a number of parameters in the wizard to model the results. As a result, order recommendations are generated, which can be purchase orders from suppliers or production orders.

Data output of the results of material requirements planning

There are three options for displaying the determined data:

Daily: If you select this method, each day in the date range will have a column.

Weekly: If you select this method, SAP Business One lists the columns by week number in the year.

Monthly: If you select this method, each month in the date range

Mobile warehouse 2025 with Versino Warehouse Pro

Moving average price in SAP Business One

Units of measure in SAP Business One

Warehouse management with SAP Business One

Consignment warehouse in SAP Business One