Discrete manufacturing places special demands - not only on the productionbut also to the systems that support them. First and foremost: ERP systems. These must be discrete manufacturing one thing above all: function. That sounds banal, but it is by no means. Because anyone who manufactures machines, devices or complex assemblies today faces challenges every day: global cost pressure, increasing quality demands and changing customer requirements. A single mistake - and the screw jams. Both figuratively and literally.

Hands-on production needs planning with foresight

Discrete manufacturing differs fundamentally from process manufacturing. While homogeneous mass products such as paints or cleaning agents are produced there, here the focus is on individual, often individually configured products. This involves welding, assembling, painting and screwing - usually in individual pieces or small batches.

That's why you need a ERP systemthat thinks for itself. One that understands what a bill of materials is - and why it changes before the first part is manufactured. Because an inflexible system not only overburdens itself, but also the people who work with it.

ERP in discrete manufacturing: More than just printing receipts

A modern ERP for the Discrete manufacturing is not an option, but a necessity. Accordingly central functions must be covered:

- Configure-to-order processesthat respond flexibly to customer wishes

- Transparent supply chains thanks to automation, approval workflows and spending limits

- Traceability and quality assurance - because nobody wants to wonder why a defective part is in the warehouse

- Demand planning with seasonal sensitivity - fed internally and externally

- Real-time KPI tracking in the warehouse - for immediately visible bottlenecks

- Production control including OEE and throughput analysis - directly in the ERP

- Global cash flow forecasts - also in several Currencies

ERP thus becomes the control centre of discrete manufacturing. Anything that is not integrated causes delays, costs and unnecessary friction.

Discrete manufacturing meets innovation

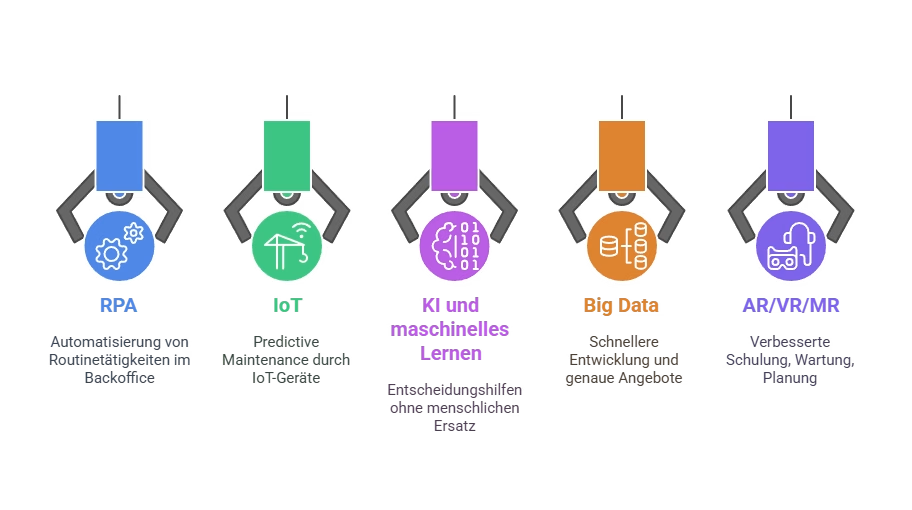

Of course Industry 4.0 also before the production does not stop there. However, not every new technology represents real progress. It is important to keep an overview - and to make targeted investments:

- RPA Automates routine activities in the back office

- Internet of Things-enabled products Predictive maintenance

- AI and machine learning offer decision support - without replacing the human being

- big data Shortens development times and increases quotation accuracy

- AR, VR and MR Improve training, maintenance and planning

In short: the Discrete manufacturing benefits from innovation - if it is used in a targeted manner.

ERP implementation: avoid pitfalls

An ERP project for the Discrete manufacturing can only be successful if the introduction is structured. Otherwise, even the best software will become a brake pad.

Just in For medium-sized companies that oscillate between standardisation and individuality, flexibility is crucial. This means configuration instead of expensive programming. Customization Yes - but with a sense of proportion, please.

Because an ERP for the Discrete manufacturing must reflect best practices on the one hand, but also incorporate company-specific features on the other.

Desire and reality

Not infrequently ERP projects do not fail because of the software but rather lack of process knowledge. So who its processes in the discrete manufacturing The best ERP system will not be able to work efficiently if you don't know exactly how it works.

What's more, if you try to integrate everything that is technically possible, you risk an overloaded, unstable system - with considerable budget risks. The bottom line is that only one thing helps here: focus on the essentials.

ERP as the key to successful discrete manufacturing

the Discrete manufacturing is complex - and requires an ERP system that can cope with this complexity. So if you want to produce successfully in the long term, you cannot do without a powerful, flexible and future-proof ERP.

ERP for discrete manufacturing - or why screws don't flow

AI for SAP Business One puts the user at the centre

Automated management of production orders

With a focus on production: Versino participates in SMS

Advanced production planning in SAP Business One