In many ERP-Every day, processes that are necessary but do not add value are carried out in the ERP systems. Employees spend valuable time manually entering orders, laboriously checking invoices or comparing receipts. As a result, these repetitive tasks tie up resources that are more urgently needed elsewhere. This is precisely where Robotic Process Automation (RPA) comes in. Software robots take over these tasks, work around the clock and document every step seamlessly. Especially for medium-sized companies In combination with the existing ERP system, RPA provides a concrete introduction to automation without having to change the entire system.

Key Takeaways

- RPA automates manual tasks in ERP systems, freeing up employees' time for value-adding activities.

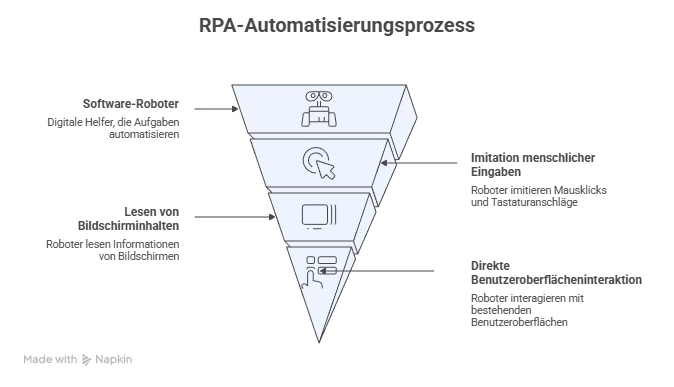

- The technology imitates human input, interacts directly with user interfaces and requires no in-depth intervention in the IT infrastructure.

- RPA shows considerable efficiency gains, particularly in financial accounting, purchasing and customer service.

- The combination of RPA with AI improves the processing of unstructured data and leads to more intelligent processes.

- Stable processes, scalability and centralised management are essential for a sustainable RPA implementation.

What is RPA - and what distinguishes it from other solutions?

Robotic process automation refers to the rule-based automation of manual tasks using specialised software robots. These digital helpers imitate human input, such as mouse clicks or keyboard strokes. They also read screen content independently. In contrast to traditional interface solutions, RPA interacts directly with the existing user interfaces. Therefore, no in-depth intervention in the IT infrastructure is required. Nevertheless, RPA does not replace complex business logic. Rather, the technology automates clearly structured processes that have a high volume and low variance at the same time.

Strategic fields of application in the ERP context

RPA is particularly suitable in areas where a high level of manual effort meets standardised processes. In financial accounting, for example, the robot performs automated invoice verification using text recognition. It also reconciles payments with bank accounts or posts receipts to the sub-ledgers. The technology is also effective in purchasing and ordering. Here, RPA automatically sends order confirmations or compares delivery dates with current ERP inventories. RPA also supports customer service by automatically forwarding tickets or creating standardised response letters. Even master data maintenance benefits considerably, as software robots validate VAT IDs and reliably identify duplicates in the system.

The combination of RPA with AI as an evolutionary step

RPA is particularly effective when companies combine the technology with AI functionalities. While RPA takes on the structured tasks, AI processes unstructured data or makes logical decisions. For example, AI recognises the type of document, while RPA carries out the subsequent processing in the ERP system. Using intelligent text recognition (OCR), the AI reads paper documents, whereupon the software robot feeds the extracted data directly into the system. The result is genuine process intelligence. Pure automation develops into dynamic and adaptive process processing that can even make suggestions for preferred Delivery on the basis of historical data.

A practical example: Automated workflow at a machine manufacturer

A medium-sized mechanical engineering company implemented RPA to optimise the entire process from ordering to invoicing. As soon as an order is received via a web form, the robot records the data and creates the order in the ERP. The system then automatically generates a shipping notification. Once the goods have been received, RPA automatically triggers the invoicing process and then reconciles the incoming payments. This procedure led to time savings of 70 % in the entire ordering process. In addition, the error rate for document entry was reduced by an impressive 90 %. Thanks to the seamless RPA logs, every action remained transparent and traceable for the company.

Success factors for sustainable implementation

For the use of RPA to work in the long term, certain requirements must be met. Firstly, the technology requires stable and standardised processes. Systems must also react robustly to errors and provide defined feedback if data is missing. Furthermore, scalability is crucial so that robots can be reused for different variants. As RPA acts like a digital employee, governance and monitoring are essential. Centralised management ensures version control and the necessary maintenance cycles. Nevertheless, RPA reaches its limits when processes are too unstructured or user interfaces are constantly changing. In such cases, prior standardisation of processes or the addition of AI modules can help.

To summarise, RPA is a fast and low-risk way to make ERP processes more efficient. By relieving employees of repetitive tasks, they gain time for value-adding activities. In combination with artificial intelligence, RPA also acts as a viable bridge to fully intelligent process automation.

Predictive maintenance: how to turn SMEs into smart factories

RPA in the ERP environment: increasing efficiency through digital process assistants

Generative AI in ERP: How LLMs are changing the role of ERP systems

Preparing the ERP future with APIs and microservices

Data quality & AI : AI can only be as good as your data