In today's intelligent world the ability to solve problems before they even arise is no longer a futuristic scenario, but a business-critical necessity. We are in the middle of a digital transformation, which presents traditional SMEs with a radical choice: Either remain in reactive mode - repairing when it is already too late - or utilise data as a strategic resource. Unforeseen downtime is the number one profit killer in production. SAP Business One no longer functions merely as an administration tool, but transforms the ERP from a passive data tomb into an active data centre. Setting the pace in production. It is the Digital platform for today's technologies, which helps SMEs to make the right decision at the crucial moment.

Read more: Predictive Maintenance: Wie den Mittelstand zur intelligenten Fabrik machtKey Takeaways

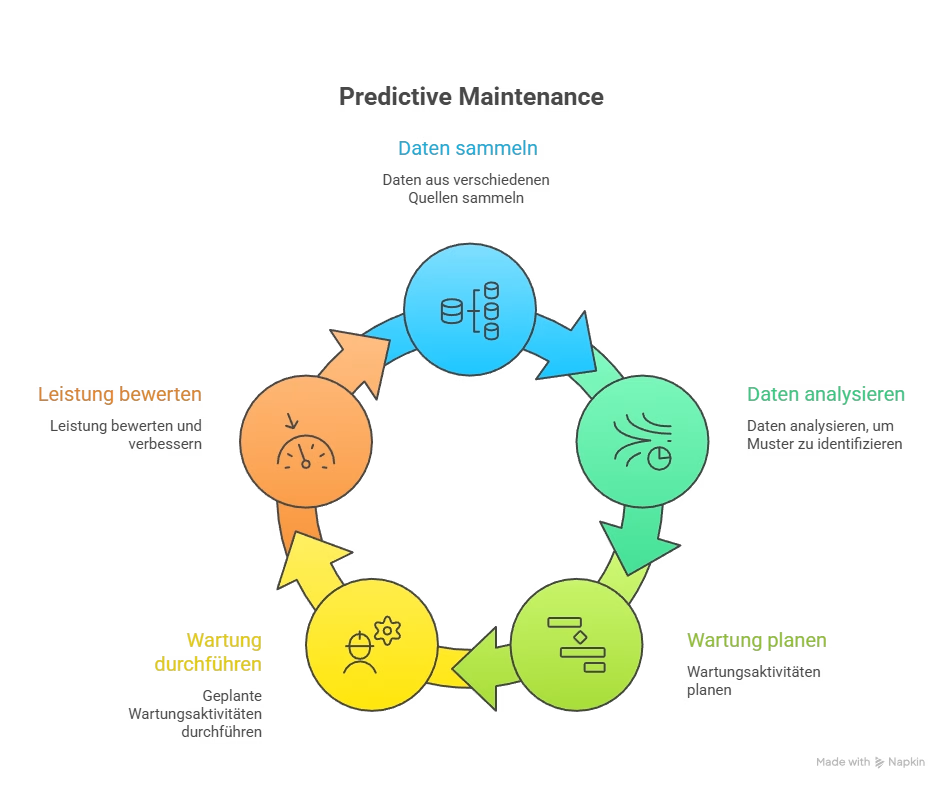

- Predictive maintenance is now a business-critical necessity for companies in order to avoid unforeseen downtimes.

- SAP Business One offers an integrated solution that bundles data from various sources and thus enables proactive action.

- Thanks to IoT and a service layer, machines and ERP can communicate efficiently with each other without the need for complex programming.

- Real-time analyses and automated workflows optimise the speed of response to maintenance requests and increase efficiency.

- Cloud technology promotes strategic flexibility and enables access to the latest innovations in predictive maintenance.

1. the „intelligent digital core“ as a strategic foundation

In practice, predictive maintenance often fails not because of the sensors, but because of isolated data silos. Without a intelligent digital core, If all information streams are bundled, any error message from a machine remains worthless. Only when sales, purchasing, production and service are integrated into a single In-memory database (SAP HANA) The necessary transparency for proactive action is created by merging the two.

Data silos are the biggest enemy of efficiency. If the status of a machine is not directly linked to the Material Requirements Planning (MRP) or the current delivery obligations in sales, predictive maintenance remains a theoretical concept. SAP Business One removes these barriers through fully integrated business processes.

„SAP Business One is the most comprehensive platform for growing businesses, already trusted by 80,000 companies.“

2. when machines talk - IoT and the bridge to ERP

The technical breakthrough is achieved through the integration of external sensors and other sources via Internet of Things (IoT). For many SMEs, terms like integration framework or Service Layer for complex IT expertise. From a strategic point of view, however, they are the decisive competitive advantage: the service layer acts as a modern API „translator“ that makes the language of the machine understandable for the business logic without the need for complex in-house programming. This makes the system highly Scalable.

SMEs in the Machine, device and component construction do not have to reinvent the wheel. Thanks to the global Partner network there are over 500 certified Industry solutions which are specially tailored to the requirements of parts production and metal processing.

The following key technologies form the framework:

- Internet of Things (IoT): The physical networking of assets and ERP.

- big data: The ability to process huge amounts of data from ongoing operations without loss.

- Machine learning: The basis for recognising real behavioural patterns beyond rigid threshold values.

3. real-time analyses: using the window of opportunity

Traditional reporting is like looking in the rear-view mirror - you can see where you have hit the wall. In the context of predictive maintenance, however, speed is everything. Thanks to the SAP HANA in-memory technology the data processing does not take place on slow hard disks, but directly in the working memory. This Real-time computing is the prerequisite for a completely new category of maintenance.

In production, the time window between the detection of an anomaly (e.g. vibration or temperature rise) and the actual machine failure can often be just a few minutes. Pervasive dashboards and Key Performance Indicators (KPIs) enable those responsible to utilise this critical „window of opportunity“. Maintenance messages must not only appear in the weekly report; they must trigger the process at the moment the risk arises.

4. automated workflows - from sensor to material procurement

An intelligent system is characterised by the fact that a warning message is automatically followed by action. In SAP Business One, the service process is seamlessly integrated with the logic of the Intelligent Suite linked. It's not just about a technician turning up, but about the entire supply chain responding:

- Sensor event: A critical value is reported via the IoT interface.

- Identification: The system organises the event using the Customer equipment card immediately to the specific object.

- Service call & SLA: A service call is made taking into account the Service level agreements (SLAs) prioritised.

- Integrated material planning: This shows the strength of the integration. The system checks the Material Requirements Planning (MRP), The system checks whether the necessary spare parts are in stock and immediately triggers an order in Purchasing if required.

- Production synchronisation: Ongoing Production orders are automatically adjusted to divert downtimes to other machines.

5. mobility - predictive maintenance on the „last metre“

The most valuable data is of little use if it doesn't leave the office. Mobile availability is the „last metre“ to success. About the SAP Business One Mobile Apps (iOS/Android) or the modern web client have service technicians directly at the machine Instant access to all relevant information.

Thanks to integrated analyses in real time, employees can view maintenance histories on site, call up technical drawings or upload photos of wearing parts directly to the service call. This transparency massively increases the first-time fix rate and makes field service a proactive part of the value chain.

6 Strategic flexibility: Cloud as an innovation accelerator

The decision between cloud and On premise today is less a question of IT infrastructure than of the speed of innovation. While on-premise offers maximum control over internal hardware, I increasingly recommend that innovative SMEs move to the cloud.

the Cloud version offers the decisive strategic advantage: You receive Access to the latest functions without being dependent on internal IT resources. Especially for predictive maintenance, where technologies such as AI and IoT are developing rapidly, the cloud enables a level of scalability that is almost impossible to achieve cost-effectively with internal hardware. You swap high upfront investments for flexible operating expenses and always remain at the forefront of technology.

Are you ready for the proactive future?

Predictive maintenance is no longer a question of company size, but of technological intelligence. The combination of an integrated digital core, high-performance in-memory technology and a seamless IoT connection paves the way for production without nasty surprises.

The next logical step is the transition from threshold-based alarms to real alarms. Pattern recognition through machine learning. The technological basis in SAP Business One is ready - the question is whether you already see your data as employees of your company.

Is your company still waiting for the next costly outage, or are you already actively putting your data to work for your productivity?

Predictive maintenance: how to turn SMEs into smart factories

RPA in the ERP environment: increasing efficiency through digital process assistants

Generative AI in ERP: How LLMs are changing the role of ERP systems

Preparing the ERP future with APIs and microservices

Data quality & AI : AI can only be as good as your data